BRC Servo Drive

- 20-150VDC 20A brushed DC servo drive.

- Step/Dir input compatible with Mach3.

- Low cost open frame design.

- High efficiency. Minimal heatsinking required.

- 14 LED indicators for easy setup and diagnostics.

- Configure with standard mini-B USB cable.

- Easy tuning with free Tuna™ software for Windows.

- Smooth silent operation. No dithering.

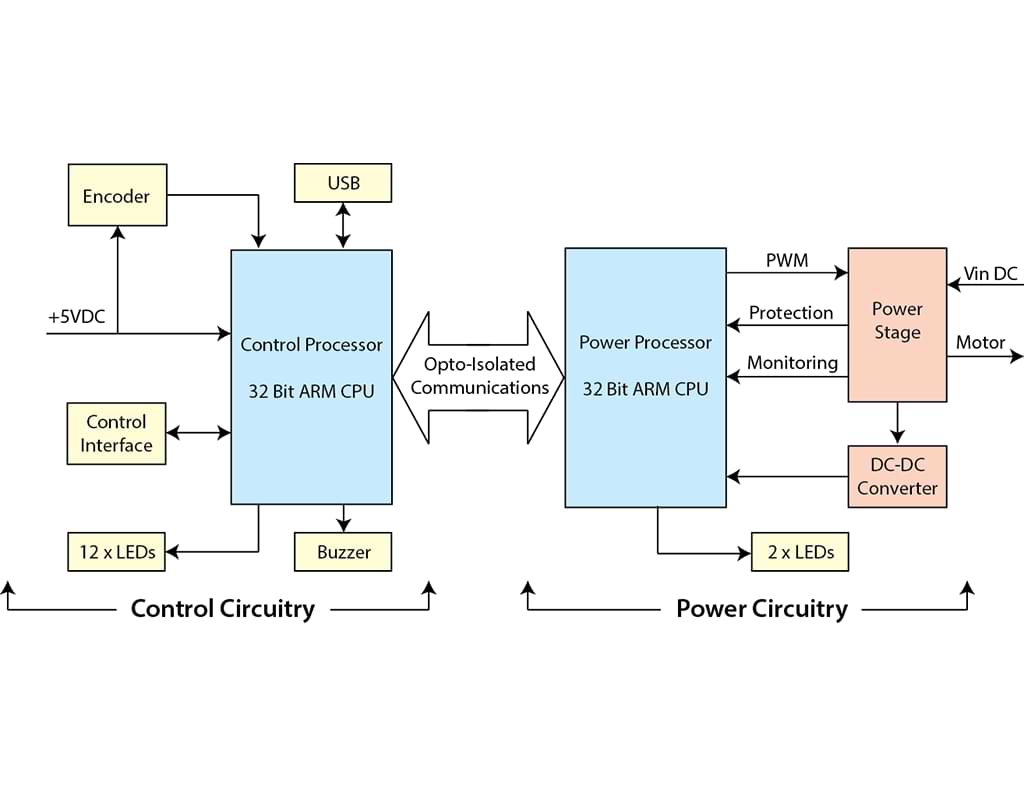

- Latest control algorithms. Dual 32bit ARM CPUs.

- Voltage, current and temperature alarms.

- High noise immunity with isolated control circuitry.

- Free worldwide shipping for 3+ units.

- Designed and manufactured in Australia to IEC/EN 61800-5-1.

Downloads:

Advanced Control Algorithms

- Supports modified PI-D (PIV) algorithm.

- Dedicated 32 bit ARM control board CPU with double precision floating point motion calculations.

- Command velocity improvement with glitch filter, sliding filter and noise filter.

- Frequency and 1/T command velocity estimation with automatic transition.

- Velocity and acceleration feed forward with time shifting.

- Stiction (static friction) and reversal compensation.

- Supports all combinations of metric and imperial hardware. Automatic calculation of electronic gearing and step multiplying with no loss of precision.

- Abnormal condition detection like saturation, following error and encoder fault.

Easy Setup and Operation

- Standard step and direction input supports popular CNC programs like Mach3.

- All control signals are isolated from power circuitry.

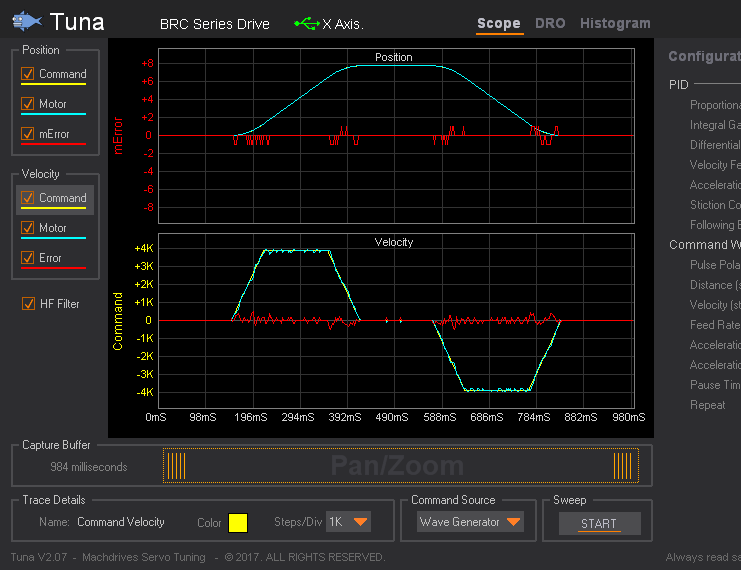

- Easy drive commissioning with free Tuna software for Windows via USB.

- 14 LED indicators show all I/O states without multimeters or oscilloscopes. Signals too fast or short to be seen are "shifted" into the visible range.

- In-built waveform generator creates tuning waveforms such as trapezoid and S-profile.

- Easy parameter configuration. Values can be keyed in directly or + and - keys can be used for live "nudging" of tuning values.

- Six channel scope with pan and zoom for easy waveform analysis.

- Digital readouts on command and motor positions.

- Real time statistical motor position error analysis and charting over multiple time intervals.

- Automatic saving of values.

- Ability to assign drive axis names and connect multiple drives at the same time.

Advanced Power Stage

- Under and over voltage monitoring and alarms. User adjustable current limit from 5 to 20A. Current limiting alert.

- High efficiency MOSFET bridge. Typical applications do not require a dedicated heatsink. Steel control cabinet wall mounting is normally sufficient.

- Dedicated 32 bit ARM CPU for power stage.

- Silent operation. No singing or dithering.

- Optional power saving mode significantly reduces drive and motor losses with no effect on performance.

- Output short circuit protection.

- Intelligent overload protection.

- Snubber circuit across motor output with additional snubbers on power rail.

- Thermal monitoring of heatsink with audible warning and shutdown.

- High efficiency DC-DC converter supplies power stage with negligible losses and spread-spectrum frequency for reduced EMI.

- Power stage is isolated from control circuitry and earth.